Dewater MAS HP 6×6

Next Generation Filter Presses for

Heavy Duty application

Dewater Filter Presses solution with innovative

technologies and modern engineering which will define

the future of filter press: lower residual moisture, high

capacity with smaller footprint, continuous automatic

work, high reliability at low investment and

running costs.

Designed and Made in Italy

Dewater MAS HP 6×6

Next Generation Filter Presses for

Heavy Duty application

Dewater Filter Presses solution with innovative technologies and modern engineering which will define the future of filter press: lower residual moisture, high capacity with smaller footprint, continuous automatic work, high reliability at low investment and running costs.

Designed and Made in Italy

Dewater HP 4×4

Dewater HP 4×4 Next Generation

Filter Press for heavy duty application

Dewater Filter Presses solution with new

technologies and modern engineering which will define

the future of filter press: lower residual moisture, high

capacity with smaller footprint, continuous automatic

work, high reliability at low investment and

running costs.

Designed and Made in Italy

Dewater HP 4×4 Next Generation Filter Press for heavy duty application

Dewater Filter Presses solution with new technologies and modern engineering which will define the future of filter press: lower residual moisture, high capacity with smaller footprint, continuous automatic work, high reliability at low investment and running costs.

Designed and Made in Italy

Technical Specifications

Heavy Duty –

4×4 Next Generation

Filter Press

Dewater SP Automatic

Automatic Filter Presses for

Medium to High capacity applications

Dewater SP is an automatic Fast Filter Press made for

diverse industrial applications. The filter press delivers

efficient & high filtration performance for filtration

applications in Mining, Metallurgical, Chemical,

Petrochemical & all other general industrial waste

water treatments.

Designed and Made in Italy

Automatic Filter Presses for Medium to High capacity applications

Dewater SP is an automatic Fast Filter Press made for diverse industrial applications. The filter press delivers efficient & high filtration performance for filtration applications in Mining, Metallurgical, Chemical, Petrochemical & all other general industrial waste water treatments.

Designed and Made in Italy

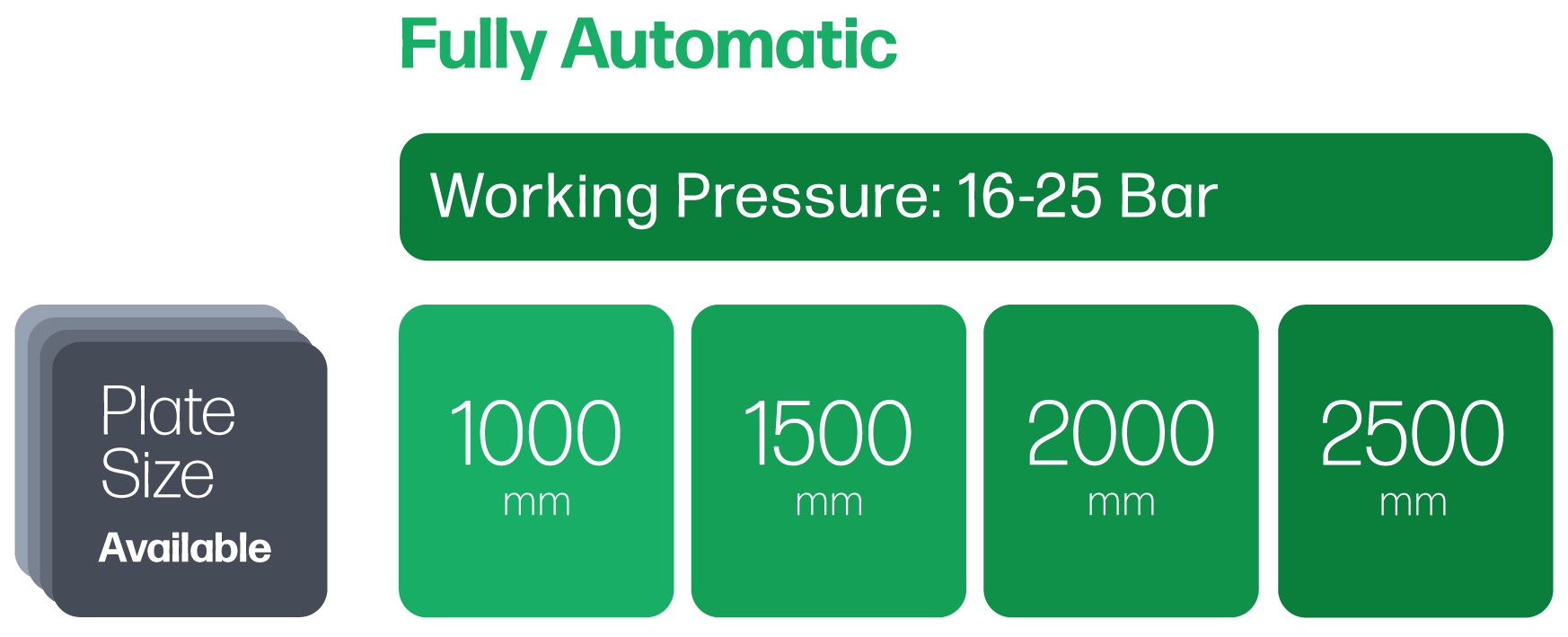

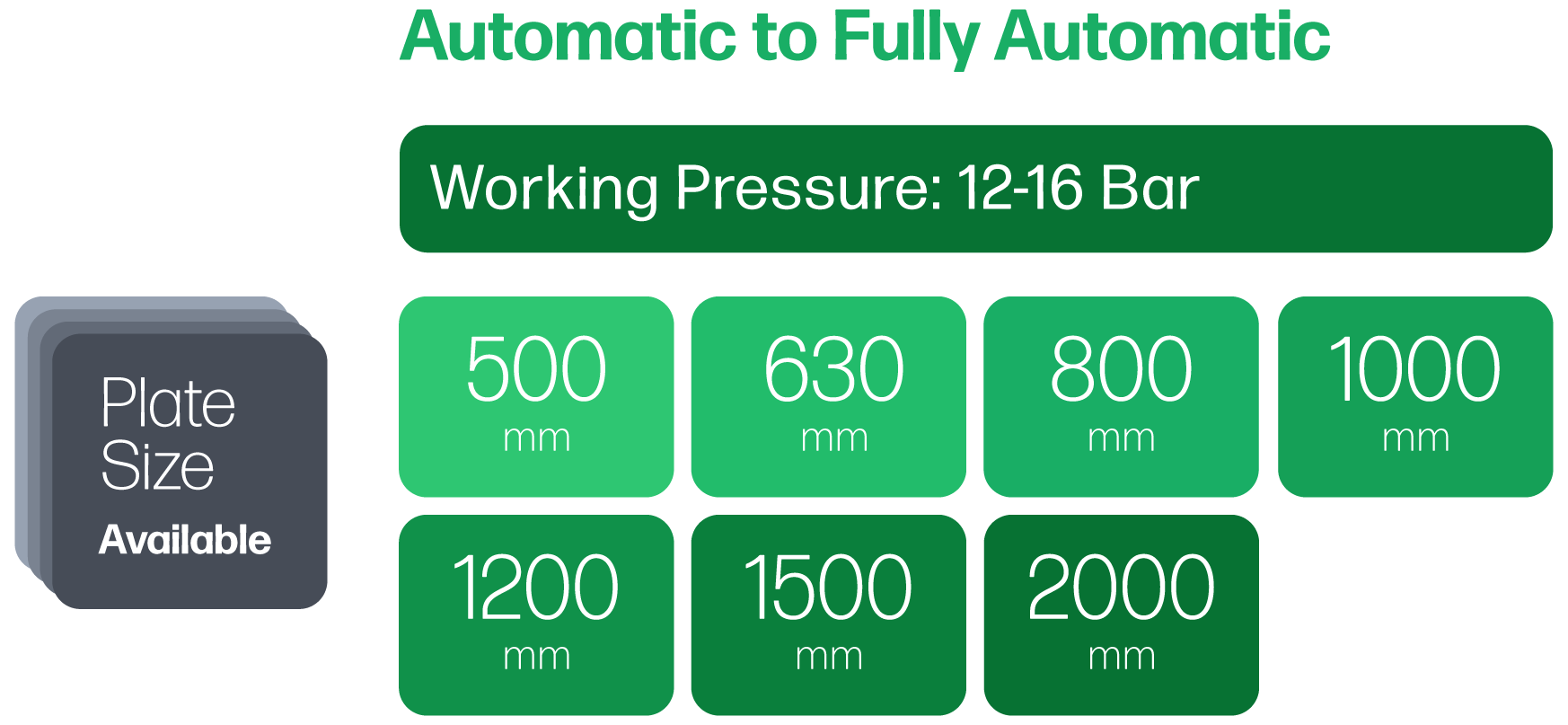

Technical Specifications

Medium to High

Capacity Filter Press

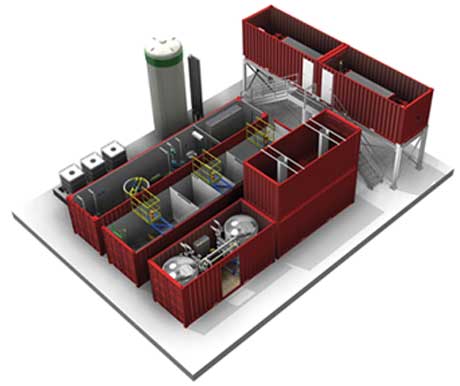

Dewater Complete

Filtration Solution

Thickening, Filtration, and

Filtered Filtered Cake Transfer Solution

Dewater has the expertise and capability to supply

a complete plant for slurry dewatering and treatment

including Thickener, Filter Press, Conveyors for filtered

cake transport & all associated ancilliaries of

the filtration plant.

Designed and Made in Italy

Thickening, Filtration, and

Filtered Filtered Cake Transfer Solution

Dewater has the expertise and capability to supply a complete plant for slurry dewatering and treatment including Thickener, Filter Press, Conveyors for filtered cake transport & all associated ancilliaries of the filtration plant.

Designed and Made in Italy

Other range of products offered

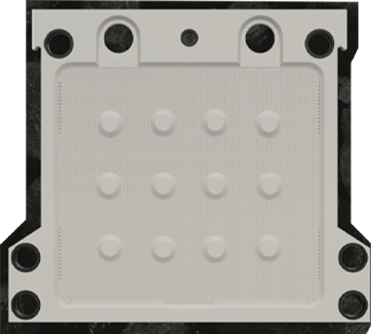

Filter Press Plates and Membranes

High Quality Chamber Plates, Membrane Plates and Interchangeable Membranes for Filter Presses installed in Mining and Metallurgical applications.

At DryTech, we specialize in cutting-edge solutions filter press plates and filter cloths designed to revolutionize the mining industry. Our filter press plates, cloths and ancillary are specially designed to meet the needs of the mining industry and are interchangeable with the original ones used in mining operations. This is a valuable feature, as it allows for easy replacement and compatibility, reducing procurement costs, delivery times and guaranteeing greater performance thanks to our engineering derived from twenty years of experience serving the mining sector.

Designed and

Made in Italy

Industrial Wastewater & Slurry Treatment Plants

COGEDE Srl. a company established in 1987 in Italy is one of the leading suppliers of Plants and engineering for industrial Wastewater Treatment Plant (WWTP) and Slurry Treatment Plant, water management and sludge dewatering in the mining industries, Tunnelling, Ceramics and Municipal Wastewater Treatment & Water Recycling and Drinking water treatment. Cogede custom designs, builds, manufactures & supplies complete plants following to specific customer requirements. They have the production facilities based in the Marche province, Italy, with their headquarter in Fano, Italy. And they supply to our customers throughout the World complete plants “Made in ITALY”. COGEDE Srl. designs and manufactures plants which are either fixed or containerised according to the customer needs and specifications. Main industries Cogede Srl. serves – Mining, Metallurgical, Tunnelling, Aggregates and Sand washing, construction and demolition waste recycling and Ceramics.

Designed and

Made in Italy